炉管(Furnace)设备工艺经验8年笔记

通知:智于博客 迁移至 芯知社区 http://blog.iccourt.com

感谢大家一直以来的支持,小编将继续努力推出更有深度,更有品质的博文,敬请期待。

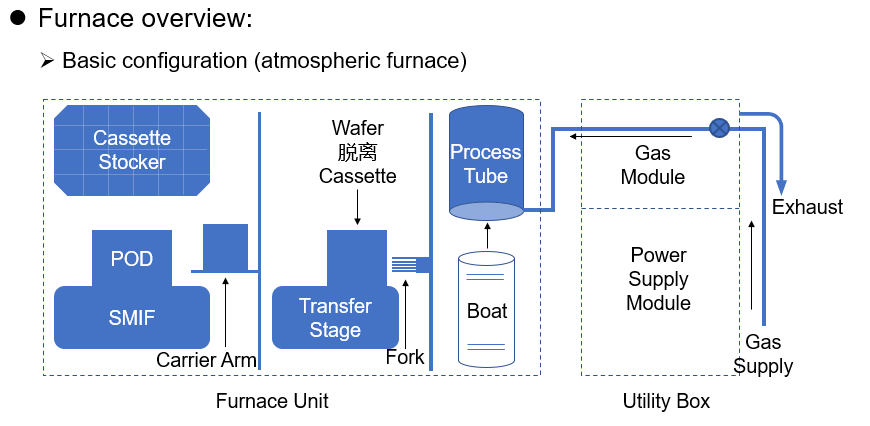

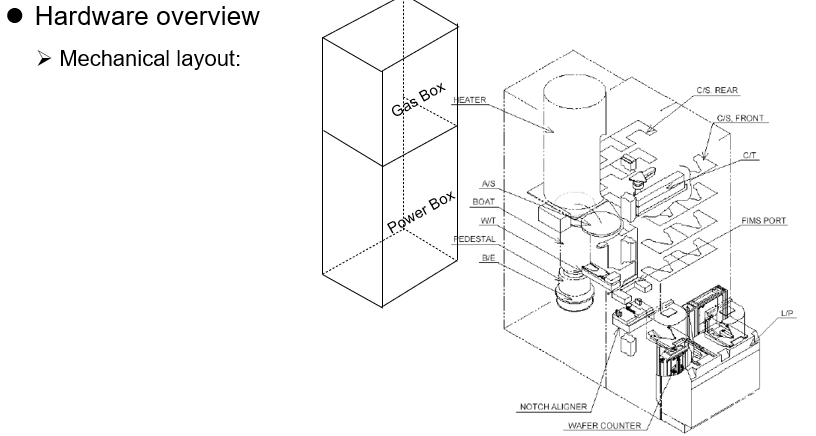

Furnace Introduction

ØFurnace concept(炉管基本介绍)

ØFurnace Type (炉管的分类)

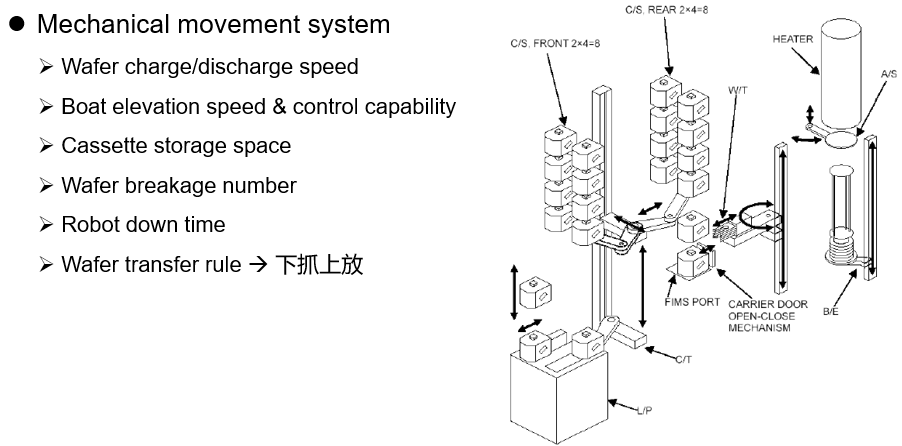

ØWafer transfer system (炉管传送系统介绍)

ØProcess application(工艺应用); AP and LP Recipe body ;Furnace Gas Flow; Profile log(温度曲线;压力曲线)

ØFurnace monitor operation flow (Wafer level 的监控)

ØFinal summary and Q&A

8年行业经验汇集于此,拿走不谢。

l分类

Ø按照厂商分:TEL / KE / ASM / CT / NAURA / SPTS(以色列)

Ø按照Process Pressure: AP / LP

Ø按照Process Temperature: High Temperature / Middle Temperature / Low Temperature

Ø按照Process function:氧化(Oxidation) ; 扩散(Diffusion)与驱入(Drive in); 退火(Anneal); 回流(Reflow); 合金(Alloy); 低压化学气相淀积(LPCVD); Si3N4; Poly-Si; SiO2(LTO/MTO/HTO); PSG/BPSG

lWhy furnace?

ØHigh throughput, 150 wafers/run

ØWell known, “simple” and “old” technology

ØAP furnace and LPCVD furnace

Ø“Cheaper”

lDisadvantage:

ØLager thermal budget, dopant lateral diffuse;

ØCan’t easy control device accurately.

Ø错误发生时,产品不易补救,报废量高

Ø石英器材消耗量大

1个Batch,process 150pcs production wafer Side dummy/fill dummy/Monitor Stocker 里面可以放2个batch

查看隐藏内容

支付宝打赏

支付宝打赏  微信打赏

微信打赏